Comet P40 Soft Wash Pump Maintenance Guide

- Posted by: Collin Steele

Congrats on your new Comet P40 soft wash pump! To help you get years of reliable service, here are the must-know tips and rules for daily use and maintenance. Even a few minutes of care can save you big headaches down the road.

1. Set Up Right the First Time

- Mount on a Stable Base: Install the pump on a solid, level surface to reduce vibration and prevent premature wear.

- Check Connections: Make sure all hoses and fittings are taped and tightened before you start. Air leaks can ruin your day (and your pump).

- Use Proper Filtration: When proportioning, always use a quality filter on your water inlet side to catch debris and avoid damaging your pump.

- Proper Bypass Set Up: If you are batch mixing, simply route your bypass line back to your batch tank. If proportioning, ensure that you have ~25 feet of bypass hose between your pump and proportioner. You can coil the hose to save space, but it’s important to have some length to your bypass hose so the liquid inside doesn’t heat up too quickly when in bypass mode.

2. Daily Operation Tips

- Prime Before Spraying: Pumps have an easier time sucking liquid out of your tank if there is already liquid present in the inlet line. To introduce liquid manually into your line before firing up the pump you can use a garden hose to feed in water.

- Don’t Run Dry: Never run your pump without water going through it. Dry running will damage the seals and diaphragms fast.

- Use a Pressure Gauge: Always have a pressure gauge installed while operating. Comet P40s typically operate around 300 PSI while spraying. Never exceed the pump’s rated pressure to avoid damage, leaks and possible injury to people nearby.

- Don’t Let It Bypass Too Long: Do not let it sit in bypass for more than 60 seconds. Heat builds up, seals melt and then you’ve got problems.

3. Flushing & Rinsing

- Flush After Every Job: Always run fresh water through your pump for at least 5 minutes at the end of every job. You can also use a bleach neutralizer as a ‘spa treatment’ for your pump internals to keep them happy.

* Why Flush? Because chemical residue (especially bleach) eats up the internals. Flushing with water is the single most important thing for pump life.

4. Storage

- Don’t Let Chemicals Sit: Never leave sodium hypochlorite in the pump or hose lines overnight.

- Cold Weather Care: If you’re in a place where it freezes, run pump antifreeze through the system before storage to prevent damage. Chemicals and cold together will crack or eat up your pump.

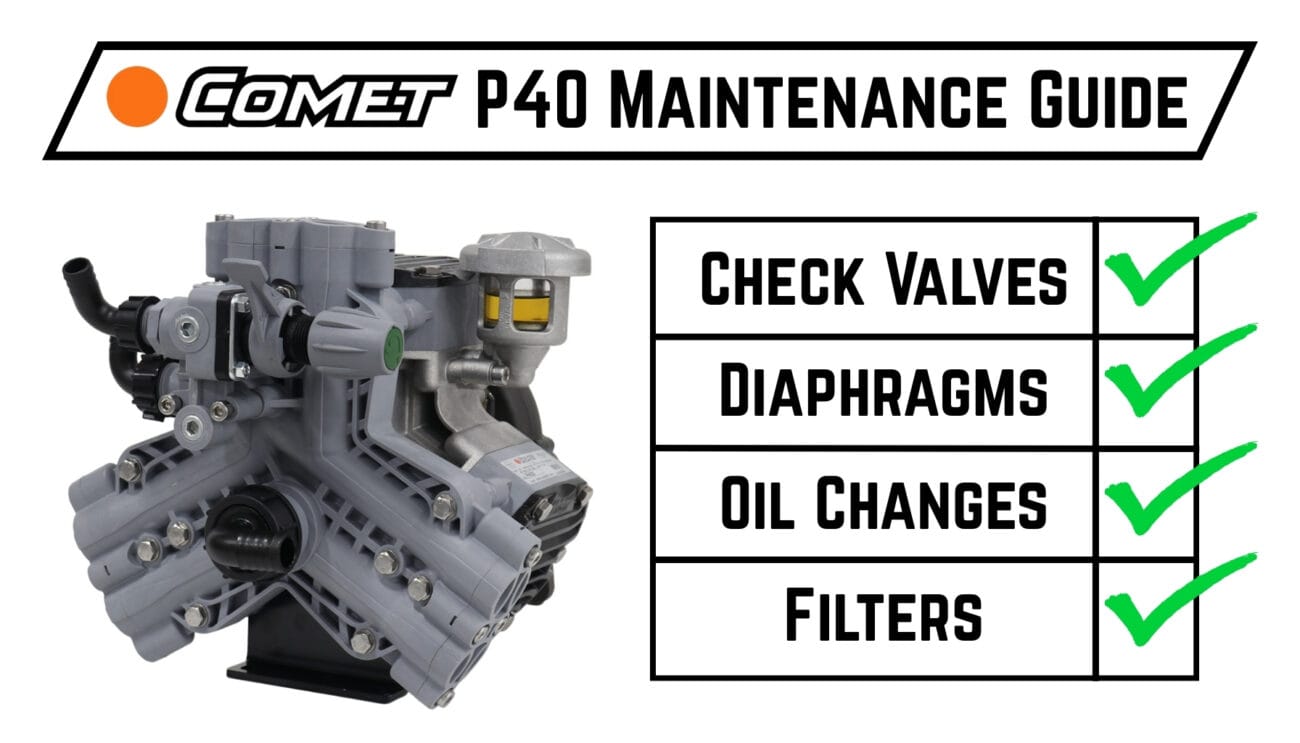

5. Oil Maintenance

- Use Correct Oils: Use only manufacturer-recommended oils. Never mix different oil types, and always refer to your manual for exact specifications.

- First Oil Change: After the first 300 hours of operation.

- Check Often: Oil should be clean and at the proper level. If oil takes on a whitish appearance, this indicates possible diaphragm rupture.

- Watch for Oil Leaks: Keep an eye out for any evident oil leaks around the pump heads and oil cup/cap area. Address leaks immediately to prevent damage and contamination.

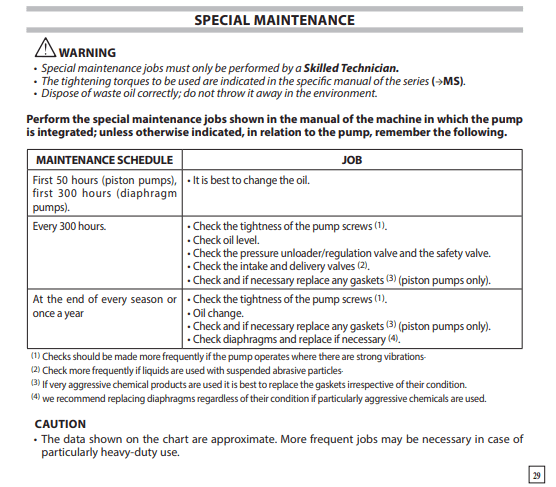

6. Special Maintenance

The Comet P40 is a diaphragm pump so always take that into account when reviewing the manufacturer’s manual and following the special maintenance recommendations below:

5. General Do’s and Don’ts

- Use the Right Chemicals: Only use chemicals approved for soft washing, never solvents or acids.

- Check for Leaks: Keep an eye on all fittings, clamps, and hoses. Air leaks will cause suction problems on the inlet side of the pump, and fluid leaks will cause low pressure on the high side of the pump.

- Keep an Ear Out: Any new noise usually means a problem. Stop and check your system if you hear grinding, squealing, or knocking.

- Replace Worn Parts Early: Seals and diaphragms are wear items and if you see leaks or notice a drop in pressure, get them replaced before it gets worse. It’s always good to have a set of replacement parts handy for when the time comes. Check out our replacement fittings:

7. Important Rules

- No Unauthorized Modifications: Changing things from the original setup can cause damage and make it harder to fix if something goes wrong. Just stick to what the pump was designed for and you’ll have fewer problems down the line.

- Use Only Recommended Parts: Always use parts and kits recommended by the manufacturer or your dealer. Avoid using random parts from other brands or hardware stores, even if they look similar or seem cheaper. If you’re not sure what part to get, just ask your dealer or check the manual before you order anything.

- Follow the Manual: Keep your owner’s manual handy. If you run into a problem or have a question you can’t answer, take a look at the manual first. You can download the Comet Diaphragm General Manual here, but keep in mind this is a general manual for Comet diaphragm pumps, so make sure you follow the specifications and procedures that apply to your Comet P40. If you need help, call us at 561-314-0761. We’re always happy to help!

- Train Your Crew: Make sure your team is familiar with the daily operations and maintenance of your pump. They should know how to troubleshoot pressure issues, change oil, add fuel, and any other daily procedures you deem necessary.

9. Video Maintenance Guides

We compiled video guides for Comet P40 repair and maintenance. These should walk you through everything you need. Check the videos below to keep your pump running at its best:

- Comet P40 Oil Change and Update

2. Comet P40 Soft Wash Pump! Complete Install & Start Up Guide!

3. Quick Fix Comet P40 Oil Leaks From Where & Why

4. P40 Soft Wash Pump Tear Down How to Maintain How to Repair

The bottom line is: take care of your pump and it’ll take care of you. Make these tips a habit and you’ll get more life out of your Comet P40 soft wash pump, with way less downtime and stress. If you ever need help or have a question, just give us a call and we’ll walk you through it!

Latest Blog Posts

If you’ve been soft washing for a while, or even if you’re just starting out, you’ve probably heard the word

...