Essential Soft Washing Tools

- Posted by: Collin Steele

The right soft wash tools can transform a potentially daunting task into a satisfying and professional outcome. Beyond removing stubborn grime, it’s equally important to protect the cleaned surfaces. In this post, we’ll delve into the essential equipment for soft washing, exploring the key components that contribute to a successful and efficient cleaning process.

Essential Soft Washing Tools

1. Pump

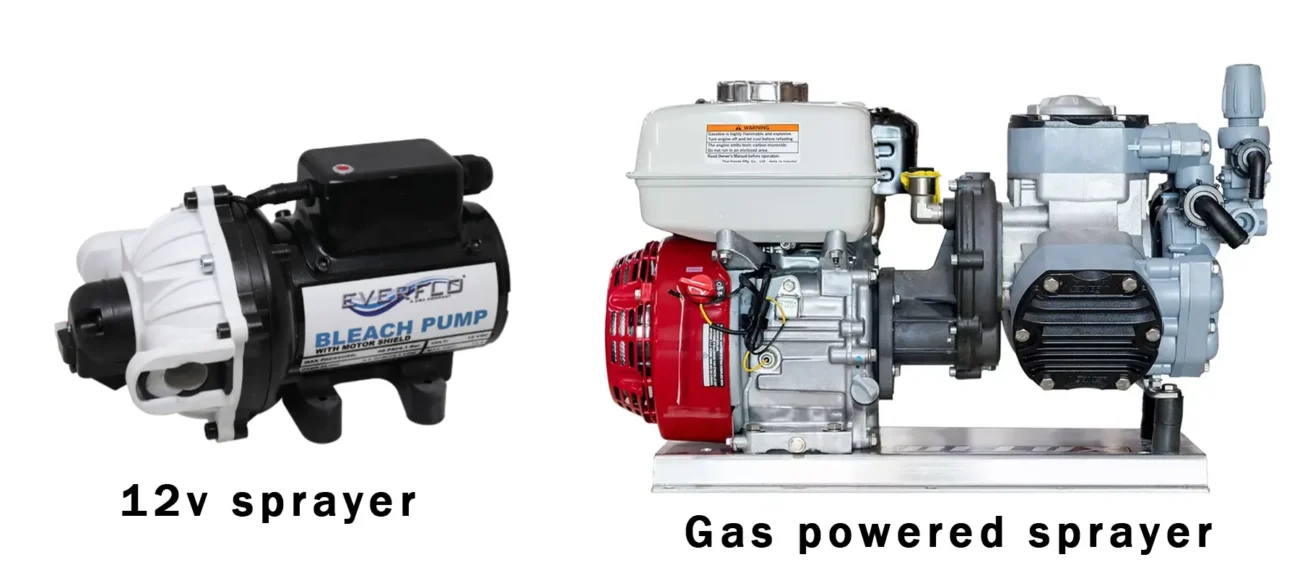

When setting up a soft wash system, selecting the appropriate pump is a crucial decision. The pump you choose can significantly impact the effectiveness and efficiency of your operations. Due to their portability, 12-volt and gas-engine-driven pumps are widely popular among soft washing professionals. While 110-volt, hydraulic, or air-driven pumps can also be used, they often require additional equipment or access to electricity at the job site. This guide will focus on 12-volt and gas-engine pump options.

The ideal pump for your soft wash system depends on your specific needs and the scale of your projects. 12-volt pumps are a cost-effective choice for residential cleaning. If you plan to tackle larger commercial buildings or houses 2+ stories high, a gas-engine pump offers greater flow and reliability but comes with a higher price tag.

2. Surfactants

Surfactants are a vital component of soft wash accessories. To improve cleaning, these viscous liquids are added to a water and sodium hypochlorite solution. Surfactants enable the cleaning solution to distribute more uniformly and deeply into dirt and grime by lowering the surface tension of the water. Surfactants also help the soft wash mix to adhere to sloped surfaces and siding allowing for a longer dwell time.

3. Proportioners

A proportioner is a tool for measuring and combining your water, chlorine, and surfactant with precision. Proportioners make sure that the cleaning ingredients are mixed in the right amounts for gentle washing to get the best possible outcomes. For professional soft wash contractors seeking precise control and efficient chemical mixing, a proportioner is an invaluable tool, making it especially easy for your employees in the field to get the right soft wash mix everytime. It streamlines the preparation of cleaning solutions, ensuring consistent quality and performance. By maintaining accurate concentrations, our proportioners contribute to the effectiveness and efficiency of the soft washing process.

4. Neutraliser

An essential item in the soft washing market is a neutralizer. Its main purpose is to bring a surface’s pH balance back to normal following chemical cleaning. A neutralizer, usually an alkaline solution, is sprayed over the surface after the cleaning solution has been applied and rinsed. The pH level is brought back to equilibrium by this alkaline solution, which also helps to neutralize any leftover acidic residue. Because some cleaning products, such as bleach or acidic cleansers, might leave behind harmful residues, this procedure is essential. By preventing more degradation and damage, neutralizing contributes to the surface’s safety for both people and animals.

5. Respirator

Working with chemicals that might be dangerous to breathe in, especially when concentrated, is a common element of soft washing. It is strongly advised that you use a respirator to safeguard your respiratory health. A respirator with organic and inorganic vapor cartridges is adequate for many mild washing applications. For those who work in soft washing and painting, our CE-Certified Soft Wash Respirator provides outstanding protection.

Soft Washing: A Step-by-Step Guide

Step 1: Mixing the Cleaning Solution

Creating the perfect cleaning solution is the cornerstone of effective soft washing. Combine water with Sodium Hypochlorite and a surfactant, ensuring accurate measurements for optimal potency. Safety is paramount; wear protective gear to avoid chemical contact.

Step 2: Setting Up Your Equipment

Assemble your pump, proportioner (or batch mix), and tanks securely. Fill your tanks with enough water, chlorine, and surfactant to last your entire job. Lay out hoses and attach appropriate nozzles. Don personal protective equipment including eye and respiratory protection.

Step 3: Applying the Solution

Spray with a constant side to side or up and down motion to ensure uniform coverage. Allow the solution to dwell, monitoring the surface and adjusting nozzle settings as needed.

Step 4: Rinsing and Post-Cleaning Care

After 10-15 minutes thoroughly rinse off the cleaning solution with clean water. Inspect the area for any missed spots and implement necessary maintenance to protect the property.

Be aware of your surroundings and ensure that all animals, plants and valuables are protected or pretreated before soft washing.

Proper Storage for Your Soft Wash Equipment

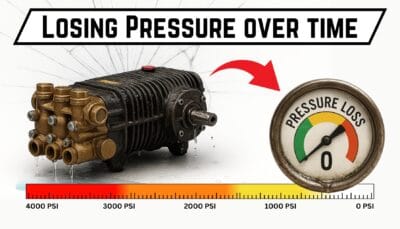

After a soft wash job, it is crucial to thoroughly rinse out your proportioner and pump. Doing this ensures that the caustic Sodium Hypochlorite does not corrode the seals and other components inside of your pump. Rodents can also pose a threat by chewing wires, building nests, and causing damage. Use deterrents, traps, and protective coverings to safeguard your equipment from these pests if storing outside.

Conclusion

Keep in mind that quality counts when it comes to soft washing gear and equipment. Purchasing dependable materials upfront ensures more effective cleaning as well as extended equipment life, which eventually translates into cost savings over time. All things considered, choosing the best soft wash tools requires assessing your requirements and taking into account factors like what type of projects you are working on, how many jobs you do a week, who you have working for you.

If you take the time to consider these aspects, you are going to be ahead of the game while delivering quality results to your customers.

Latest Blog Posts

If you’ve been soft washing for a while, or even if you’re just starting out, you’ve probably heard the word

...